-

Lignosulfonate Lignin

-

Sodium Lignosulfonate

-

Calcium Lignosulfonate

-

Potassium Lignosulfonate

-

Sodium Lignosulfonate Liquid

-

Magnesium Lignosulfonate

-

Ammonium Lignin Sulfonate

-

Ferrochrome Lignosulfonate

-

Polycarboxylate Superplasticizer Powder

-

Polycarboxylic Acid

-

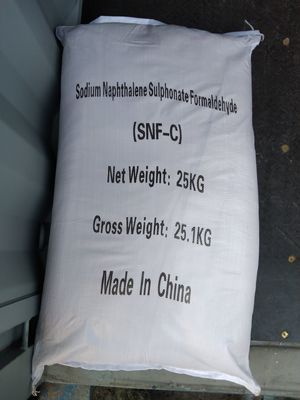

Sodium Naphthalene Formaldehyde

-

Lignosulfonate Dispersant

-

Dispersing Agent MF

-

Dispersing Agent NNO

-

Sodium Gluconate

CAS 36290-04-7 Sodium Naphthalene Formaldehyde Concrete Water Reducing Agent

| Place of Origin | CHINA |

|---|---|

| Brand Name | ATET |

| Certification | ISO |

| Model Number | SNF-A |

| Minimum Order Quantity | 1MT |

| Price | 500USD-800USD |

| Packaging Details | 20KG/BAG,25KG/BAG,50KG/BAG,500KG/BAG,550KG/BAG,600KG/BAG, |

| Delivery Time | 7-10 DAYS |

| Payment Terms | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability | 3000MT/MONTH |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Appearance | Yellow Brown Powder | Solids Content (%) | 92min |

|---|---|---|---|

| Content Of Cl- (%) | 0.3max | PH Value | 7-9 |

| Liquidity Of Cement Paste (mm) | 240min | Na2SO4 Content (%) | 5max |

| Highlight | Sodium Naphthalene Formaldehyde CAS 36290-04-7,36290-04-7 Water Reducing Agent,Sodium Naphthalene Formaldehyde Agent |

||

Sodium Naphthalene Formaldehyde is used as concrete additive

Naphthalene series superplasticizer is a condensation of naphthalene sulfonate formaldehyde which is obtained by sulfonation and condensation reaction of industrial naphthalene as raw material. This series of products have good adaptability to cement, strong dispersion effect, no retarding. Low bleed air, high water reduction rate, plastic protection early strength enhancement. The workability of newly mixed concrete can be greatly improved by using this agent. Increase slump, reduce water-cement ratio, increase concrete compactness, can adapt to various conditions of concrete construction, to ensure the performance of hardened concrete.

The naphthalene-based superplasticizer is a non-air-entraining high-efficiency water reducing agent synthesized by the chemical industry. Chemical name Naphthalene sulfonate formaldehyde condensate, which has strong cement particle dispersibility. Naphthalene-based high-efficiency water reducer can be divided into high-concentration products (Na2SO4 content <3%), medium-concentrated products (Na2SO4 content 3%-10%) and low-concentration products (Na2SO4 content >10%) according to the content of Na2SO4 in its products. At present, most naphthalene-based super plasticizers have the ability to control the Na2SO4 content below 3%, and some advanced companies can even control it below 0.4%.

Performance

1. When the strength and slump of the crucible are basically the same, the amount of cement can be reduced by 10-25%.

2. When the water-cement ratio is constant, the initial slump of concrete is increased by more than 10cm, and the water-reducing rate can reach 15-25%.

3. There is a significant early strength and enhancement effect on cockroaches, and the strength increase is 20-60%.

4. Improve the work ability of concrete and comprehensively improve the physical and mechanical properties of concrete.

5. It has good adaptability to various cements and is compatible with other types of concrete admixtures.

6. It is especially suitable for use in the following concrete projects: fluid concrete, plasticized concrete, steamed concrete, impervious concrete, waterproof concrete, natural curing precast concrete, steel and prestressed reinforced concrete, high strength ultra high strength concrete .

7. The slump of concrete has a large loss over time, and the slump loss in the half hour is nearly 40%.

| NO | Index items | Test Results |

| 1 | Appearance | Meets the requirement |

| 2 | Solids content (%) | 92.86 |

| 3 | Content of cl- (%) | 0.12 |

| 4 | PH value | 8.09 |

| 5 | Liquidity of Cement Paste (mm) | 248 |

| 6 | Na2SO4 content (%) | 4.84 |

| 7 | Air Content(%) | 1.62 |

| 8 | Water-reducing rate | 18.9 |

|

Temporal Distribution for setting (min) |

Initial Setting time | 90 |

| Terminal Setting time | 90 | |

| Corrosion to Steel Bars | None | |

Packaging and storage

1. Powder products are made of chemical fiber woven bags, lined with plastic film bags, each bag net weight (40±0.2kg) or (25±0.2kg) or (750±0.2kg), can also be customized according to customer requirements.

2. Powder products should be stored in dry and ventilated special warehouse, products such as damp caking can be crushed or dissolved into water agent use does not affect the actual effect.

FAQ:

Q1. Which payment is available for your company?

Re: T/T, L/C, D/A, D/P, Western Union, MoneyGram

Q2. How can I get the sample?

Re: We provide you free sample. But you should pay for the postage. When we have a formal transaction, we will refund the postage of this sample.

Q3. How can you guarantee the goods you offer is qualified?

Re: We can provide sample, COA, MSDS and etc to help you insure the quality. And we promise every batch of product will be tested in the factory, and they can only leave the factory after the quality is qualified.

Q4. How can I get your best price?

Re: We will provide you timely market information and the fluctuation trends of raw material to help you determine the most appropriate time for an ord

![]()